Yakli Light Film Custom LED Ceiling Manufacturers Processing Custom Acrylic Sheet

Basic Info.

| Model NO. | Sheet material, coil material |

| Kind | Transparent Plastic Sheet |

| Water Absorption | 0.2%~0.3% |

| Contraction Percentage | 0.4%~1.4% |

| Tensile Strength | 41~50MPa |

| Nontoxic | Reach |

| Impact Strength | High Impact Strength |

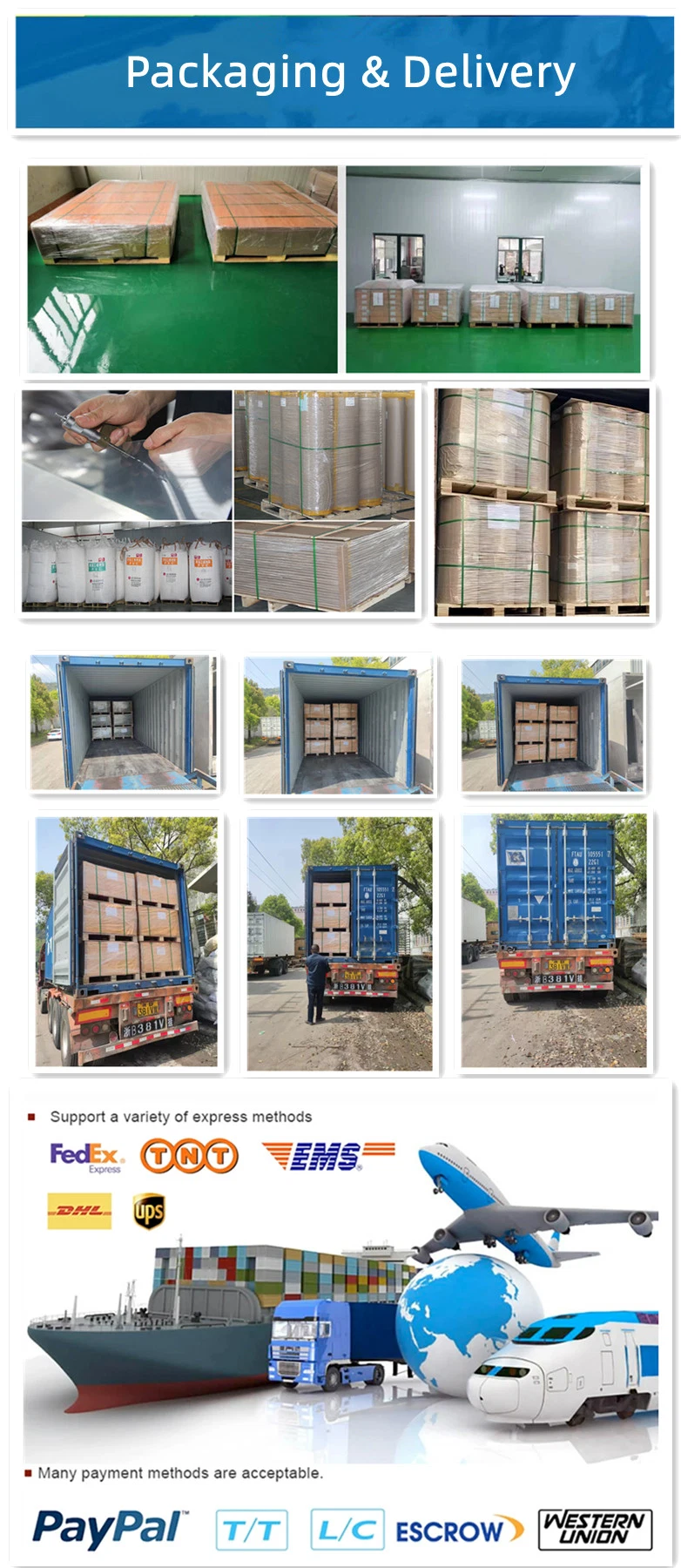

| Transport Package | Bundle Inside, Veneer Pallet Outside. |

| Specification | 1220mmX2440mm |

| Trademark | partners |

| Origin | China |

| HS Code | 3920510000 |

| Production Capacity | 3000tons/Month |

Product Description

performance parameter

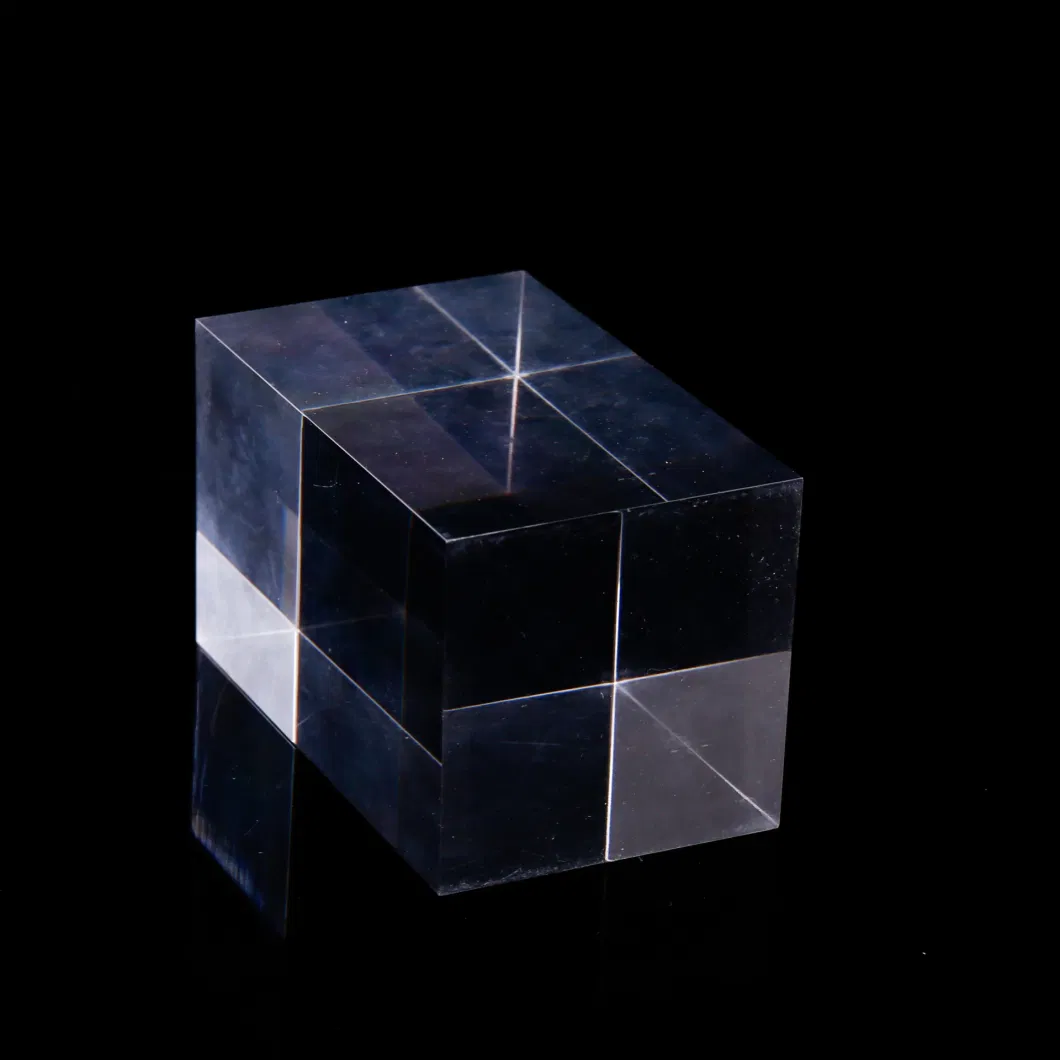

Acrylic sheet

Acrylic board with crystal general transparency, light transmittance of more than 92%, with dye colored acrylic board and has a very good display color effect, in addition, acrylic board: has excellent weather resistance, high surface hardness and surface gloss and good high temperature resistance. Acrylic plate has good processing performance, according to the production process can be divided into casting type and extrusion type two. It can be either hot forming (including molding, blow molding and vacuum blister molding) or mechanical processing methods such as drilling, turning, washing, cutting, etc. Microcomputer-controlled mechanical cutting, scraping and engraving.

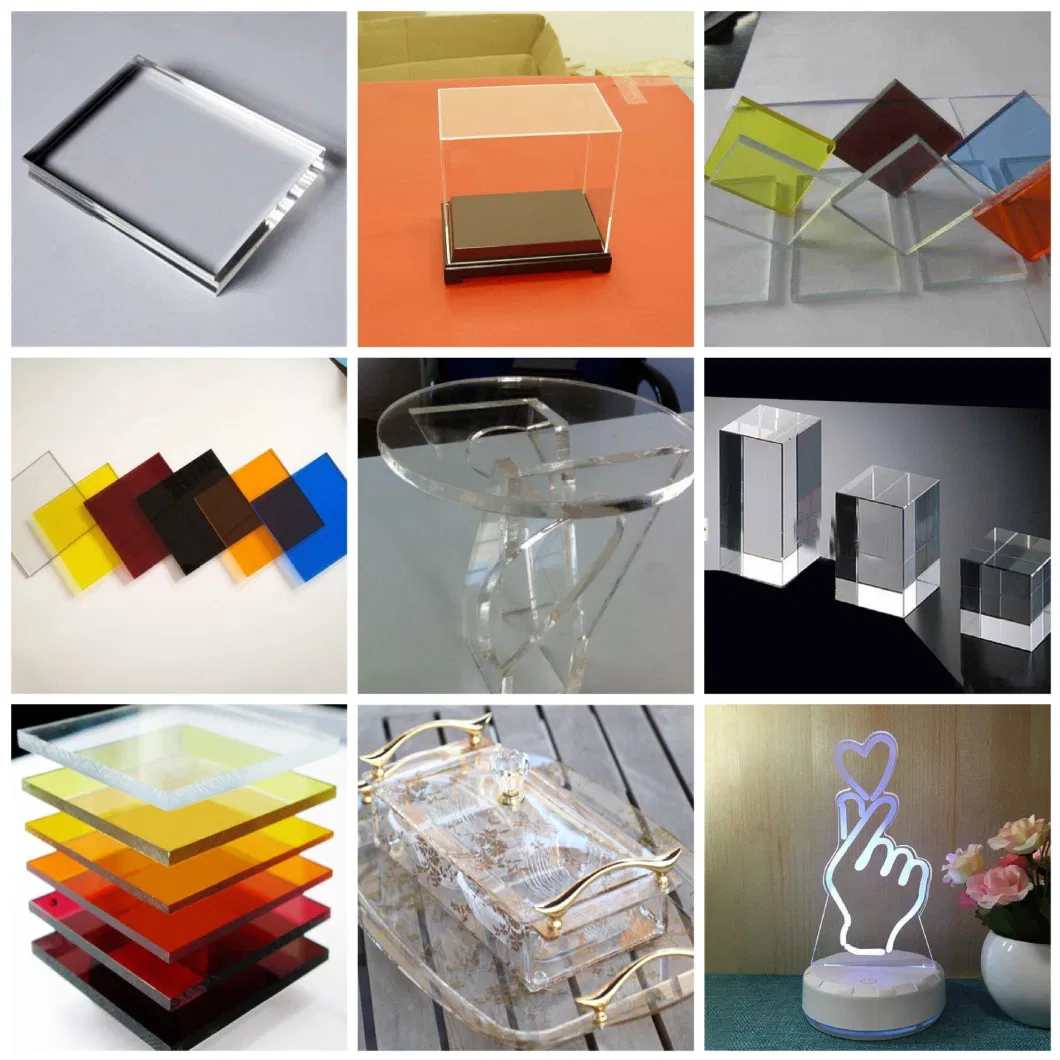

Acrylic is mainly used for

(1) sculpture, decoration, handicraft production. (2)Jewelry, cosmetics, mobile phone, electronic products and other display products .(3)mechanical window, mold equipment panel window, baffle accessories .(4)fish tank furniture and other acrylic has the advantages of light weight, low price, easy to secondary processing and forming.

Advantages of acrylic casting board:

I. Optimal performance/price ratio:

Partners in the industry to advocate and implement the performance/price optimization of acrylic board, to ensure that the same quality under the circumstances of low price, users spend the least money to buy the best products.

Two, hardness:

Hardness is one of the Partners that can best reflect the production process and technology of pouring acrylic plate, and it is an important link in quality control. Partners can reflect the purity of raw material MMA, plate weatherability and high temperature resistance, etc. Partners directly affects whether the plate will shrink, bend and deform, whether the surface will appear chapped during processing. Partners is to judge one of rigid index of quality stand or fall of press gram force board. Green spring pouring acrylic plate has the highest Partners index of the same domestic products. The average Dalloway Partners is about 89 degrees.

III. Thickness Tolerance:

The control of plate thickness tolerance is an important embodiment of quality management and production technology. The thickness tolerance of acrylic plate is controlled within +0.2mm.

IV. Transparency/whiteness:

Strict raw material selection, advanced formula follow up and modern production technology, to ensure the acrylic board excellent transparency and pure whiteness. The fire threw the cloth and it was crystal clear.

V. Enrich diversity:

In addition to the conventional transparent board, frosted board, color board and other production, but also to undertake the production of a variety of special plate. Such as patterned cloth board

VI. Powerful technical support:

The thickness range from 0.2mm to 50mm is optional. And in the use of the production process to provide free consultation and technical guidance.

Seven, strict quality inspection team:

Partners has a well-trained, conscientious, meticulous quality inspection team. From raw material production to finished product packaging cutting into the warehouse and out of the warehouse to achieve layers of checks, in strict accordance with the quality system standards to grasp the quality.

VIII. The best sales service:

Partners always put the interests of customers in the first place, always adhere to the "high quality, environmental protection, professional, fast" business philosophy, sales to take the pre-sale, sale, after-sales service.

| Material | PMMA | Heat softening temperature | ≥105ºC |

| manufacturing technique | Pouring/extrusion | weather fastness | Atmospheric aging resistance type |

| density | 1.2G/CM3 | packaging | Paper/film |

| impact strength | >16KG/CM3 | thickness | 1.9-60 mm |

| tensile strength | >61KG/CM3 | distortion temperature | 78 ºC or higher; Can be hot bending |

| specification | 1.22x2.44/1.22x1.83(zero cut) | ||

| light transmittance | 92%(limited colorless transparent type); Opaque/translucent | ||

| performance | Good chemical resistance, better than most other plastic materials | ||

| surface | It can engrave, spray paint, screen printing, UV etc | ||

| hardness | The highest hardness index is an average Dalloway hardness of 90 degrees | ||

| colour | Red, yellow, blue, green, orange, black, milky white, fluorescent green through, tea through... | ||

| processing method | Drilling, turning, milling, cutting (saw, laser, CNC) | ||

| durable years | As long as 5~8 years, green environmental protection waste materials can be completely recycled, recycling is simple and easy | ||

| be often used | Machine/equipment accessories (such as cover/cover), billboards, signboards, signs, signs, display boards Light box. Easy to clean and maintain, keep the product appearance as new all the year round, reasonable design, rain and moisture proof | ||

product picture

About our company